RETROFITTING FOR MIXING PLANTS

We have 10 years of rich experience in renovating existing concrete mixing plants. Through reasonable rectification, technical transformation can be carried out on the existing mixing plant. At the same time, it can significantly improve the output capacity of the mixing plant. By installing stronger mixers, adjusting weighing and measuring equipment, and updating control equipment, the competitiveness of the mixing plant has been decisively improved.

Even under difficult spatial conditions, a reasonable solution can be found. For example, it is usually possible to easily replace existing disc mixers with dual horizontal axis intermittent mixers.

In addition to comprehensive planning and production of the supply scope for special designs, we also provide services from installation to operation through our reliable and experienced team based on on-site requirements.

BELT CONVEYORS

Belt conveyor is a continuous conveying equipment that uses conveyor belts as traction and load-bearing components to transport materials through the movement of conveyor belts that carry materials. Its structure is simple, operation is stable and reliable, energy consumption is low, environmental pollution is small, it is easy to control and achieve automation, management and maintenance are convenient, and it can achieve continuous transportation under continuous loading conditions. It is widely used in the fields of electricity, chemical industry, metallurgy, coal, etc., and is the most important modern bulk material conveying equipment.

SCREW CONVEYORS

Screw conveyors are mainly used for conveying powders, particles, and small materials with certain fluidity. Our spiral machine is currently widely used in concrete mixing plants, asphalt mixing plants, feed, chemical and other industries; It can be used for transporting various materials such as cement, fly ash, mineral powder, sand, ice, etc. Product features: Made of high-quality steel pipes, with good overall rigidity. Double pitch blades can reduce the degree of compression during material transportation. Adopting high-quality gearbox, heavy-duty design, with high torque, low noise and other characteristics. Optional universal joint for easy installation and adjustment of the steering device. Equipped with high-quality suspension bearings and tail bearings, easy to install.

PULSE DUST COLLECTOR

JHT's new electronic pulse dust collector is a new generation product developed based on the characteristics of dust recovery. Its main function is to thoroughly filter, recover, and reuse the dust generated during the production, transportation, and storage of powdered materials. Effectively solved the problem of dust pollution and saved valuable building resources.

Product features: high purification efficiency, large gas processing capacity, stable performance, easy operation, long service life of filter bags, small maintenance workload, suitable for mechanical, metallurgical, rubber, flour, chemical, pharmaceutical, carbon, building materials, mining and other units.

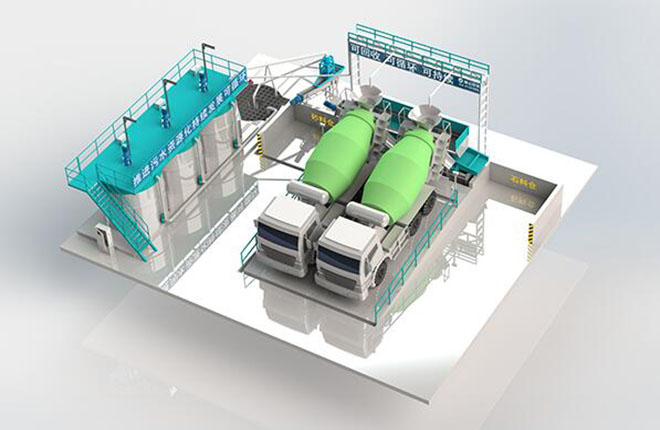

CONCRETE RECYCLING SYSTEM

The concrete recycing systems is the core equipment of the concrete recycling system, mainly used to clean, separate and recycle the sewage from tank trucks and the sand and gravel in residual concrete. The machine adopts foreign concrete recycling technology in its design, combining the characteristics of drum separation and spiral screening separation. It has made significant improvements to the vulnerable parts, with simple operation, intelligent control, and no need for personnel to supervise during use. It is convenient and fast, saving customers a lot of manpower, material resources, and financial resources.

The slurry recovery device is used in conjunction with a sand and gravel separator. After cleaning, the slurry overflowing from the concrete flows through the drainage ditch to the concrete slurry tank. To prevent sedimentation, the slurry in the concrete slurry tank is always kept in a mixed state. When in use, it can be directly pumped to the mixing plant to achieve full recycling and utilization of sand and gravel materials, cement, and slurry.

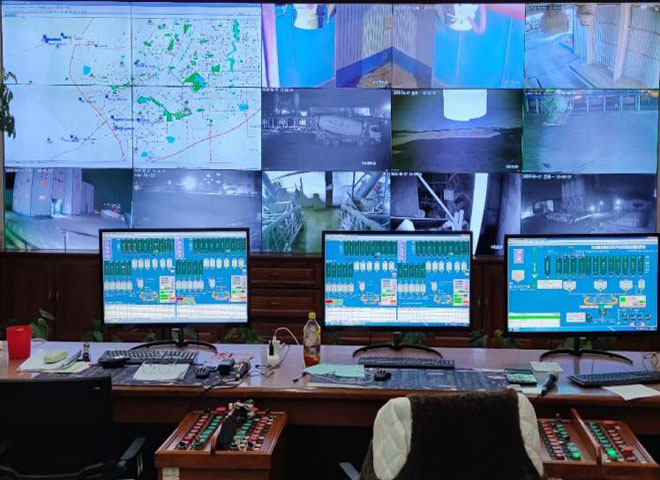

AUTOMATION SYSTEMS

JHT has developed specialized control automation systems for commercial concrete, high-speed rail, engineering, dry powder mortar, bucket station mode, pipe pile station, asphalt station, etc. based on the different requirements of mixing plant equipment. There are Chinese, English, and Russian versions available. At the same time, customized development can be carried out according to the special process requirements of the equipment purchased by users.

JHT has launched a "maintenance free" mode, making system maintenance more convenient and efficient. Users can fully maintain the Kyle series control system on their own, thereby breaking the heavy reliance of end customers on industrial control system manufacturers.

BOLTED TYPE SILOS

The bolted type silos provided by JHT is a new type of silo that can be transported to the construction site and assembled with bolts before use. This type of silo adopts laser cutting and one-time compression molding. It has the advantages of short construction period, convenient installation, convenient transportation, transferability, and reuse. JHT not only provides silos, but is also committed to providing customers with turnkey solutions for the storage and transportation of various bulk powders.

Anchor rod bolted type silos are widely used for export container transportation in concrete mixing plants, dry mortar plants, mines, hydraulic engineering, tunnels, bridges, highways, docks, bulk material transportation, and transportation of large vehicles in areas with inconvenient access.

JHT uses high-quality accessory suppliers to ensure the long-term stable operation of the concrete mixing plant. The mixer adopts BHS or Sigma; The screw conveyor adopts WAM or Sigma; Pneumatic butterfly valve adopts WAM or Sigma; The pneumatic control components are sourced from Taiwan’s AIRTAC and others