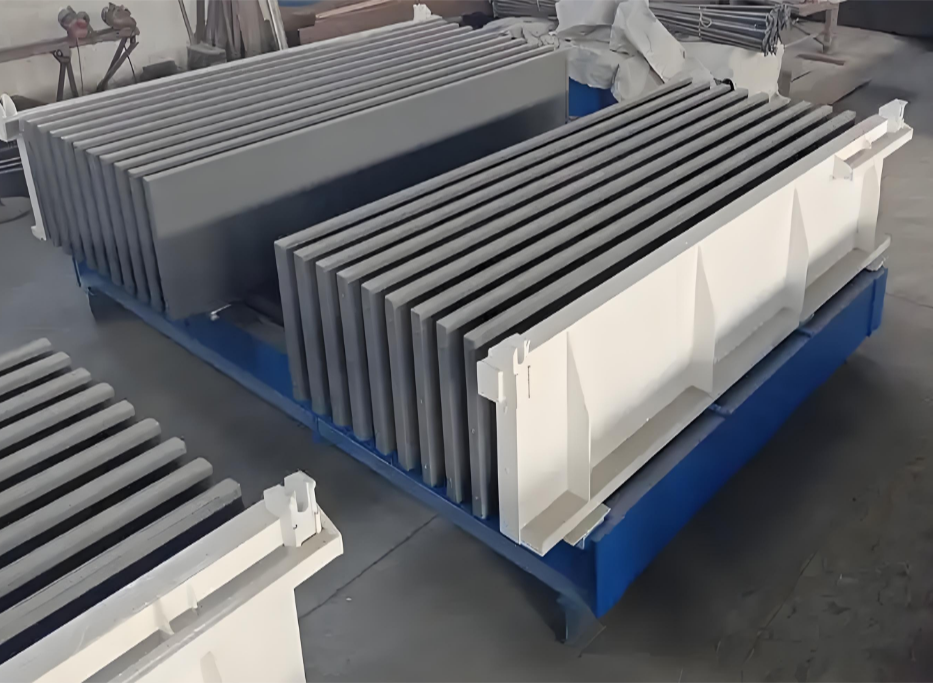

JHT's existing steel mold products include: (square) box culvert series, comprehensive pipe gallery, straight pipe gallery, wall panel series, U-shaped drainage ditch series, oval drainage ditch series, U-shaped cable trench series, ecological slope protection (retaining wall) series, L-shaped slope protection (retaining wall), prefabricated building series, rainwater collection and storage series, railway product series, etc., covering industries such as municipal, power, water conservancy, transportation, communication, landscaping, ecological governance, etc.

JHT can customize other types of irregular steel molds according to customer needs.

- Durable and long-lasting, using high-quality steel plates for molds

- Good sealing performance, no leakage of slurry or water in the mold

- Accurate size, CNC milling of irregular parts

- Quick opening and closing, hinge quick snap positioning pin

- Durable and non deformable, with a reasonable structure and reinforced ribs

- Adjustable size, modular design, one machine for multiple uses to reduce costs

- Smooth and flat, with aesthetically pleasing product shaping

- The panel has a wide range of styles and materials to choose from, making it easy to replace and cost-effective

- JHT concrete molds rely on continuously innovative technology and processes, as well as professional and comprehensive production and processing equipment

- A comprehensive pre-sales and after-sales system, personalized customized solutions, highly favored by domestic and foreign customers

- Our products are exported to Southeast Asia, the Middle East, Africa, Russia and other countries and regions

- JHT molds rely on continuously innovative technology and processes, as well as professional and comprehensive production and processing equipment

- A comprehensive pre-sales and after-sales system, personalized customized solutions, highly favored by domestic and foreign customers

- Strict production process

Raw material rust removal, laser cutting, one layer of primer, three layers of topcoat (or hot-dip galvanizing) - Durable and sturdy

The heavy-duty H-beam chassis reduces the impact of vibration symmetry during the production process. The batching machine and weighing hopper are made of 6mm steel plate, and the water and gas pipelines are made of galvanized pipes - 7 * 24-hour work

Excellent performance accessories are the guarantee for long-term operation of equipment: BHS or SICOMA concrete mixers, ABB or Marathon motors, WAM powder accessories, AIRTAC pneumatic components, Schneider Electric - Control system saves 50% -70% of operators

Control software can enable one computer to control two production lines or three production lines. By using Ethernet cables to transmit signals, remote operation and production can be achieved

1. Design your own concrete mixing plant based on site and functional requirements

2. For those with manufacturing capabilities, JHT can provide technical drawings (overall or partial); Reduce transportation and procurement costs

3. Renovation of old concrete mixing plants: will increase productivity by 10-20%.

JHT adopts decentralized shared production; Centralized procurement of supporting parts; We have achieved a low price, high-quality service system.

LEARN MORE ABOUT THE PRODUCT

Share your phone number, call you!