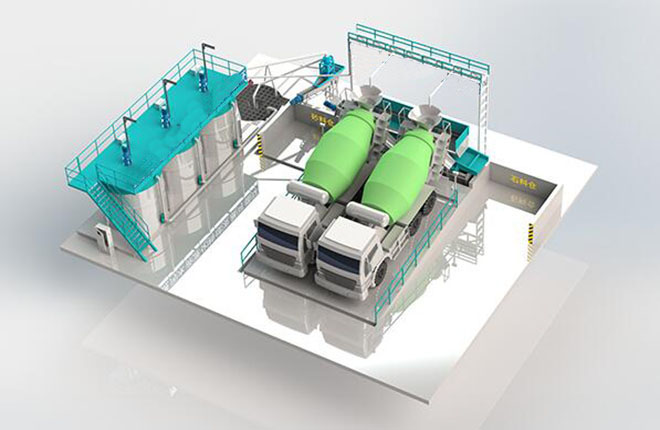

The concrete recycing systems is the core equipment of the concrete recycling system, mainly used to clean, separate and recycle the sewage from tank trucks and the sand and gravel in residual concrete. The machine adopts foreign concrete recycling technology in its design, combining the characteristics of drum separation and spiral screening separation. It has made significant improvements to the vulnerable parts, with simple operation, intelligent control, and no need for personnel to supervise during use. It is convenient and fast, saving customers a lot of manpower, material resources, and financial resources.

The slurry recovery device is used in conjunction with a sand and gravel separator. After cleaning, the slurry overflowing from the concrete flows through the drainage ditch to the concrete slurry tank. To prevent sedimentation, the slurry in the concrete slurry tank is always kept in a mixed state. When in use, it can be directly pumped to the mixing plant to achieve full recycling and utilization of sand and gravel materials, cement, and slurry.

- The overall open structure design, maintenance and use are more convenient and efficient;

- New high-frequency linear screening technology, cleaner and faster separation effect;

- Realize sewage concentration regulation inside the tank and automatically supply clean water;

- Intelligent allocation of sewage concentration, saving enterprise water resources;

- Sewage reflux system combined with secondary surface sand treatment system;

- The separated fine sand surface sand and stones are recycled and reused;

- The tank body is equipped with anti overflow pipelines to avoid pollution outside the site;

- PLC intelligent fully automatic control with fault identification system.

| Mode | Concrete screening capacity | Production capacity | Size (mm) |

Power (KW) |

Weigjt (KG) |

| JSF30型 | 30T/H | 180 concrete plants | 4500*1700*2190 | 14 | 4000 |

| JSF40型 | 40T/H | 240 concrete plants | 9840*3500*3950 | 19 | 8000 |

| JSF60型 | 60T/H | 270 concrete plants | 9840*3500*3950 | 19 | 8000 |

- Strict production process

Raw material rust removal, laser cutting, one layer of primer, three layers of topcoat (or hot-dip galvanizing) - Durable and sturdy

The heavy-duty H-beam chassis reduces the impact of vibration symmetry during the production process. The batching machine and weighing hopper are made of 6mm steel plate, and the water and gas pipelines are made of galvanized pipes - 7 * 24-hour work

Excellent performance accessories are the guarantee for long-term operation of equipment: BHS or SICOMA concrete mixers, ABB or Marathon motors, WAM powder accessories, AIRTAC pneumatic components, Schneider Electric - Control system saves 50% -70% of operators

Control software can enable one computer to control two production lines or three production lines. By using Ethernet cables to transmit signals, remote operation and production can be achieved

1. Design your own concrete mixing plant based on site and functional requirements

2. For those with manufacturing capabilities, JHT can provide technical drawings (overall or partial); Reduce transportation and procurement costs

3. Renovation of old concrete mixing plants: will increase productivity by 10-20%.

JHT adopts decentralized shared production; Centralized procurement of supporting parts; We have achieved a low price, high-quality service system.

LEARN MORE ABOUT THE PRODUCT

Share your phone number, call you!