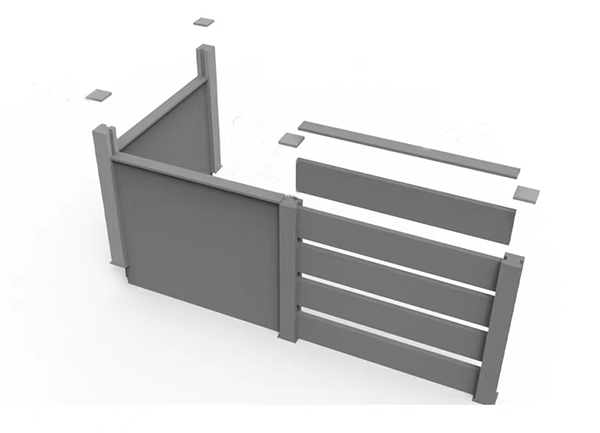

Prefabricated fence is a new type of fence structure, and the production of its wall panels is completely completed by the manufacturer. After meeting the factory standards, they are directly transported to the construction site for assembly. The installation process of this type of fence is relatively simple and does not require additional construction, thus avoiding the influence of other factors on the wall during the construction process and fundamentally improving the quality of construction. Prefabricated fences are generally composed of columns, wall panels, pressure tops, and column cap components, all of which are pre ordered from the factory. After the completion of the foundation construction, the prefabricated components installed on the upper part are assembled on site in the order of columns, insert plates, pressing tops, and column caps. During the assembly process, small lifting equipment can be used to complete it, which is very convenient. Prefabricated walls can be classified into precast concrete structures, steel column+lightweight wall panel structures, and hybrid structures, which have multiple advantages and can meet the needs of different projects

Prefabricated fences have advantages such as durability, low cost, short construction period, diverse and beautiful shapes.

Installation is not affected by factors such as geographical terrain. It can be widely used in many fields such as community walls, school walls, factory walls, municipal walls, villa walls, substation walls, etc.

- Beautiful appearance. The prefabricated wall design is exquisite and unique, with antique, European, and other shapes, especially suitable for urban municipal construction.

- Reuse. Prefabricated walls can be disassembled, assembled, and reused, saving more costs and reducing project costs.

- Easy installation. The construction unit can install according to the product manual and drawings, which is more convenient than cast-in-place.

- Short construction period. The construction period of prefabricated walls is only one-third of that of brick walls, greatly accelerating the construction speed.

- High security. The physical properties of prefabricated walls are superior to brick walls, including compressive strength and ultimate bending strength.

- Low maintenance costs in the later stage. Prefabricated fence is composed of multiple components, and some damaged components can be partially replaced, reducing maintenance costs.

- Strict production process

Raw material rust removal, laser cutting, one layer of primer, three layers of topcoat (or hot-dip galvanizing) - Durable and sturdy

The heavy-duty H-beam chassis reduces the impact of vibration symmetry during the production process. The batching machine and weighing hopper are made of 6mm steel plate, and the water and gas pipelines are made of galvanized pipes - 7 * 24-hour work

Excellent performance accessories are the guarantee for long-term operation of equipment: BHS or SICOMA concrete mixers, ABB or Marathon motors, WAM powder accessories, AIRTAC pneumatic components, Schneider Electric - Control system saves 50% -70% of operators

Control software can enable one computer to control two production lines or three production lines. By using Ethernet cables to transmit signals, remote operation and production can be achieved

1. Design your own concrete mixing plant based on site and functional requirements

2. For those with manufacturing capabilities, JHT can provide technical drawings (overall or partial); Reduce transportation and procurement costs

3. Renovation of old concrete mixing plants: will increase productivity by 10-20%.

JHT adopts decentralized shared production; Centralized procurement of supporting parts; We have achieved a low price, high-quality service system.

LEARN MORE ABOUT THE PRODUCT

Share your phone number, call you!